Contact Guo

Guo

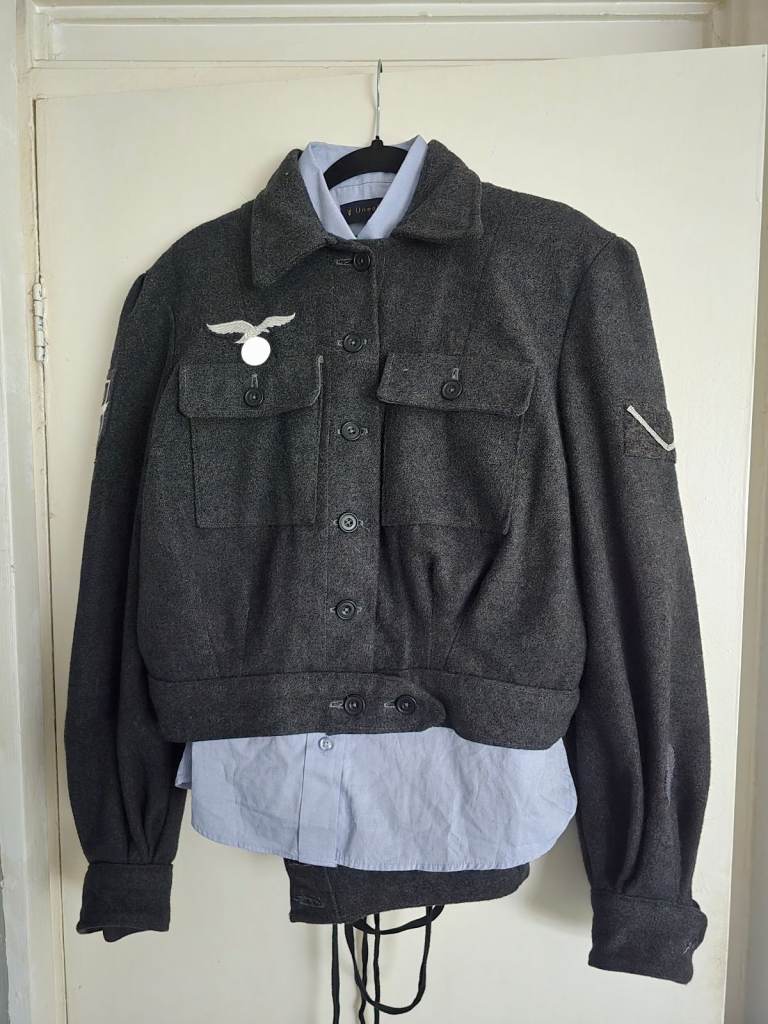

Posting for 2+ yearsNJbinglab PFA filtration apparatus

Lyme Regis, Dorset

£800

1 of 1

Email address verified

Description

PFA (Perfluoroalkoxy) filtration devices have a wide range of applications in the new materials industry, particularly in environments that require resistance to corrosion, high temperatures, and chemical stability. Here are some typical applications:

1. Chemical Filtration

PFA materials exhibit excellent chemical resistance, making them suitable for filtering and separating various chemicals. They can withstand strong acids, bases, and organic solvents. In the new materials industry, PFA filtration devices ensure efficient and reliable operation while preventing corrosion or reactions that might occur with other materials in harsh chemical environments.

2. High-Purity Material Processing

In the manufacture of semiconductors, photovoltaic materials, and other high-purity chemicals, PFA filtration devices are used to filter out impurities and ensure the final product’s purity. PFA’s low adsorption characteristics make it an ideal material for use in filtering delicate substances like silicon, metal oxides, and optical coatings.

3. High-Temperature Applications

PFA has high thermal stability and can operate at elevated temperatures for extended periods, making it ideal for high-temperature synthesis, pyrolysis, and decomposition processes. PFA filtration devices protect the filtration system from thermal damage, ensuring efficient filtration and a long service life.

4. Nanomaterial Separation and Filtration

In the synthesis and application of nanomaterials, precise particle size separation and filtration are crucial. PFA’s smooth surface and low tendency to adsorb fine particles make it an ideal choice for effectively filtering and purifying nanomaterials during their production, ensuring minimal material loss.

5. Precision Filtration of Liquid Chemicals

The new materials industry often requires the precise filtration of liquid chemicals to remove solid impurities or particles. PFA filtration devices, with their excellent chemical inertness and wear resistance, are widely used in these high-demand applications, ensuring that the liquid remains uncontaminated during the filtration process.

6. Environmentally Friendly Solutions

Many processes in the new materials industry involve hazardous chemicals or waste treatment. PFA filtration devices not only efficiently filter these substances but also minimize environmental impact. Their resistance to chemicals and pollution makes them reliable in handling toxic waste and ensuring safer disposal.

In conclusion, due to its corrosion resistance, high-temperature stability, chemical inertness, and wear resistance, PFA filtration devices are widely used in the new materials industry across several critical fields.

Posted: 27 days ago

Ad ID: 1492064663

Details

Stay Safe

"Only access Gumtree from gumtree.com and do not follow links sent by other users"

"Share photos and ask lots of questions about the items you are buying and selling"

"If an ad or reply sounds too good to be true, it probably is"

"Use the 'Reply to ad' button for your safety and privacy"

"Don't reply to email addresses hidden in text and pictures"

"Beware of fake Gumtree, eBay or escrow sites and invoices"

1 of 6